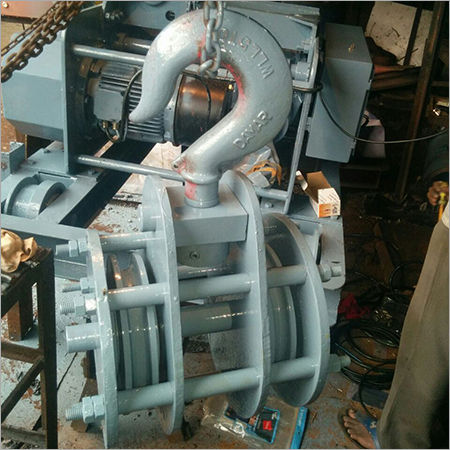

Shank Hook

MOQ : 1 Unit

Shank Hook Specification

- Condition

- New

- Working Presssure

- As Per Requirements

- Usage

- to lift and transport heavy loads.

- Material

- Alloy Steel

- Crane Type

- Other Cranes

- Application

- Warehouse, Factory, Workshop, Construction, Material Yard

- Color

- Grey

- Lifting Capacity

- As Per Requirements Tonne

- Limit Switch

- No

- Emergency Stop

- Yes

Shank Hook Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1-20 Days

- Main Domestic Market

- All India

About Shank Hook

Being one of the largest companies we are engaged in manufacturing and supplying a wide range of Shank Hook. These products are highly acclaimed for the strong and sturdy construction and longer durability. Our products are manufactured from a team of skilled engineers and efficient workers of the industry. All these items needs less maintenance and are resistant to corrosion and heat.

Features:

- Heat resistant

- Very powerful

- High quality alloy steel

Versatile Application & Sturdy Build

Engineered to function seamlessly in demanding environments, our Shank Hook effortlessly handles heavy loads in warehouses, construction sites, workshops, material yards, and factories. Its alloy steel construction ensures optimal strength, while the customizable lifting capacity aligns with your operational needs.

Comprehensive Safety Features

Safety is a top priority, with an integrated emergency stop mechanism included in every Shank Hook. The absence of a limit switch is offset by high-quality materials and precise engineering, promoting reliable operation during critical lifting tasks.

FAQs of Shank Hook:

Q: How is the Shank Hook used for lifting and transporting heavy loads?

A: The Shank Hook is attached to cranes or hoisting systems, securely connecting to heavy objects for safe lifting and movement. Its design allows efficient handling of various shapes and sizes of loads across warehouses, workshops, and other industrial environments.Q: What are the benefits of using an alloy steel Shank Hook in a manufacturing or warehouse setting?

A: Using an alloy steel Shank Hook provides exceptional durability, higher load-bearing capacity, and resistance to wear and deformation, which ensures reliable and long-term operation even under the toughest working conditions.Q: When should I consider installing a new Shank Hook in my facility?

A: A new Shank Hook is recommended when upgrading or replacing lifting equipment, especially if increased lifting capacity, enhanced safety features, or improved performance is required to match the needs of your operations.Q: Where can the Shank Hook be installed and utilized most effectively?

A: The Shank Hook is highly effective in locations like warehouses, factories, workshops, construction sites, and material yardspractically anywhere that requires heavy load management through crane systems.Q: What is the process for determining the correct lifting capacity or working pressure for this hook?

A: Lifting capacity and working pressure are customized as per client requirements. Our team evaluates your operational needs, including load types and frequency, to recommend the most suitable configuration for your specific environment.Q: How does the emergency stop feature improve operational safety?

A: The emergency stop feature enables immediate halting of operations in case of possible hazards or system malfunctions, minimizing the risk of accidents and ensuring a safer working environment for operators.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Crane Hook assembly Category

Crane Hook

Minimum Order Quantity : 1 Unit

Usage : Industrial

Size : Customized

Color : Black

Product Type : Crane Hook

Condition : New

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS